ABOUT NANGA

Established in 1941, NANGA was founded at the foot of Mount Ibuki, in Maibara. Our founder, Akira Yokota started with the goal of wanting to discover the unknown. To discover the unknown, Yokota merged groundbreaking technology with high end materials that has helped thousands of explorers get to their destination. Our name, "NANGA," was adopted from the Himalayan mountain "NANGA PARBAT." The mountain towers at over 8000 meters and is the ninth highest mountain in the world. Notoriously named “Killer Mountain,” it is responsible for numerous deaths and to this day still considered dangerous. At NANGA, our philosophy is to produce responsible and relevant products that help you get to where you want to be. For over 70 years, NANGA has demonstrated excellence through technology and continues to dominate in its field.

MADE IN JAPAN QUALITY

At NANGA, quality control, safety features, and customer satisfaction never get overlooked. Our attention to detail is how we developed our brand and is embedded in its philosophy. Only using ethically sourced European white duck down, all of our products undergo serious quality tests before being put to use.

CATEGORY

TECHNOLOGY(Nanga)

TECHNOLOGY 01

YKK × NANGA

NANGA x YKK parts which reduce snagging and catching

Our sleeping bags are equipped with specialized YKK parts on zipper sliders to minimize snagging and catching of the fabric

When using a sleeping bag, there is a risk of the zipper catching on the super-thin fabric and preventing the opening and closure of the bag. If severely snagged, the zipper may even cause damage to the fabric. To mitigate such problems, we have attached special YKK parts to the zipper sliders. These parts are developed to diminish the gaps in the zipper slider that causes the snagging, resulting in fewer occurrences of the fabric getting caught as well as reduced damage to the fabric in case of such events. Furthermore, the parts are made from lightweight resin (weighing 1.6 g per piece) with phosphorescent features for easier operation in the dark.

Due to the concave design of the specialized YKK zippers, the fasteners guide the fabric towards the center, reducing any chance of snagging or catching.

With our phosphorescent technology, finding your zippers in your dark tent will no longer become a hassle.

Due to the concave design of the specialized YKK zippers, the fasteners guide the fabric towards the center, reducing any chance of snagging or catching.

With our phosphorescent technology, finding your zippers in your dark tent will no longer become a hassle.

TECHNOLOGY 02

SOLID STRUCTURE

The next-level sleeping bag construction

All NANGA sleeping bags are constructed following a trapezoid box baffle pattern structure which brings out the full potential of down. This simple yet sophisticated pattern structure allows any user to absorb the maximum amount of heat possible. The sleek design of our sleeping bags realistically tailors to the human body making it the most efficient in size and capacity.

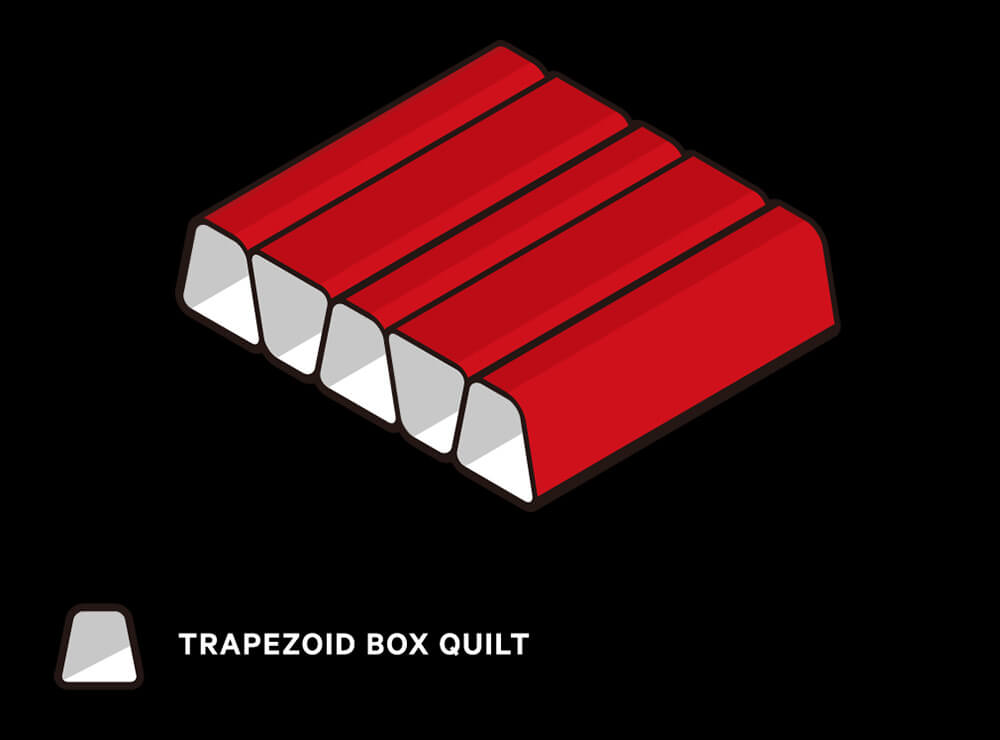

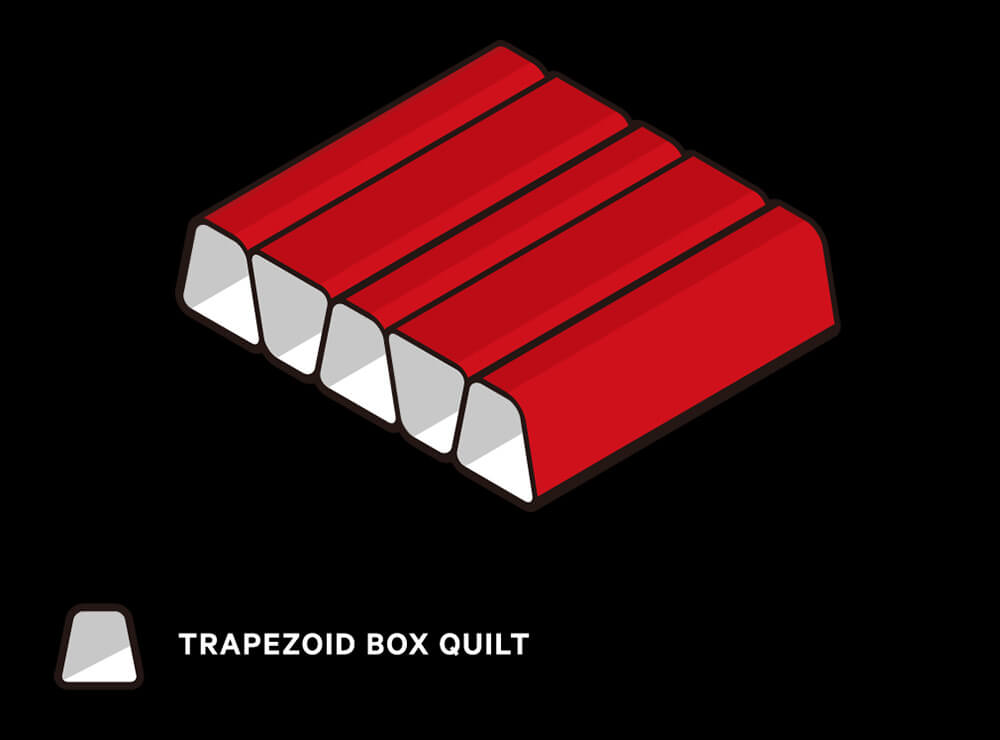

01. Trapezoid box baffle structure

What makes this pattern structure so efficient is that it prevents the down from bunching up, and also plays a role in reducing the overall weight of the sleeping bag. As the geometric structure supports each other, the full potential of the down is maximized. By reducing the heat radiation, it eliminates any potential bunching, and evenly distributes even heat throughout the sleeping bag.

02. Foot box

A distinguishing feature of this structure is that it prevents the down from bunching up, and allows for a reduction in weight. Because each of the boxes supports each other, the full loft potential of the down is maximized, and by reducing any diminished heat radiation through potential bunching, heat retention is efficiently distributed throughout the bag.

03. Shoulder warmer & draft tube

Our shoulder warmer and draft tube prevents any cold air from entering the sleeping bag.

*This feature is only available with our trapezoid box quilt models

04. Three-dimensional hood

During the cold seasons, its crucial to keep your head warm. The three dimensional hood equipped in specific models blankets your head, and functionally retains the heat so you can stay warm longer. The fastener was designed near the top of the sleeping bag, making zipping up and down your sleeping bag a breeze.

About the Mateirals(Nanga)

ABOUT THE MATERIALS 01

FUNCTION

About Functionality

Introducing the functionality that integrates NANGA's technology and philosophy

At NANGA, we only work with the finest materials in order to create high quality products. Through rigorous tests, our skilled artisans meticulously hand select the imported European white duck down that was shipped overseas to us in Japan. A sophisticated refining process is a crucial step in our development process as it maximizes the potential of the characteristics of the down.

By using the locking drawstring it is possible to adjust temperature and fit.

Insulating material in the shoulder area prevents warm air from escaping. Equipped primarily on 3 and 4 season sleeping bags.

Internal tube blocks cold air from coming in through the gaps in the zipper, preserving warmth. Equipped primarily on 3 and 4 season sleeping bags, same as the shoulder warmer.

Equipped with YKK5C. Considered to be the optimal zipper for sleeping bags based on strength testing by YKK.

The regular size has a max length of 210cm and a max width of 80cm, making for a comfortable bag. We also offer long and short versions.

ABOUT THE MATERIALS 02

CONSTRUCTION

About Product Construction

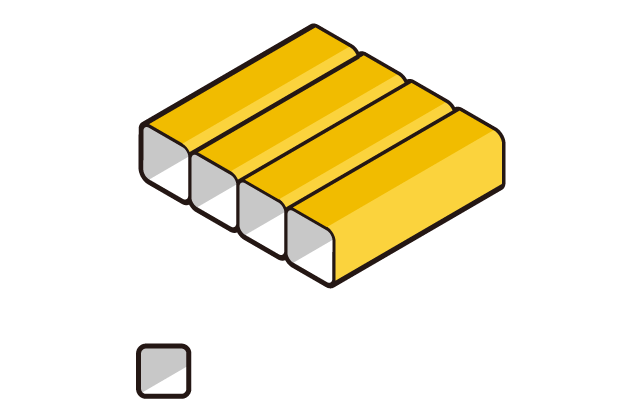

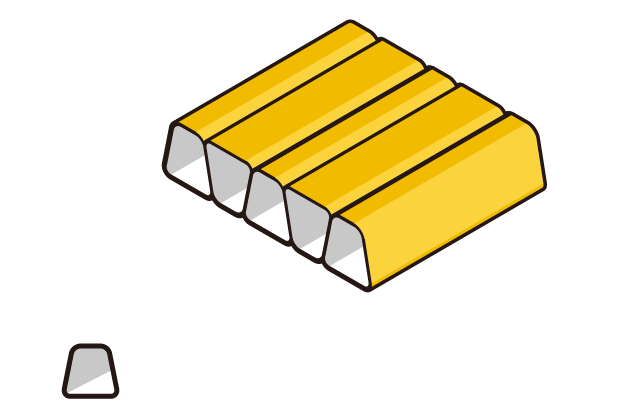

The 3 quilting structures used by NANGA. We leverage a deep understanding of the strengths of each type to identify the optimal application for each product.

This sleeping bag features a new level of technology, with a trapezoid box baffle structure and solid structure which maximizes the full potential of down, and allows stress-free and efficient heat retention no matter what position you sleep in. By narrowing the feet area, we have successfully reduced weight.

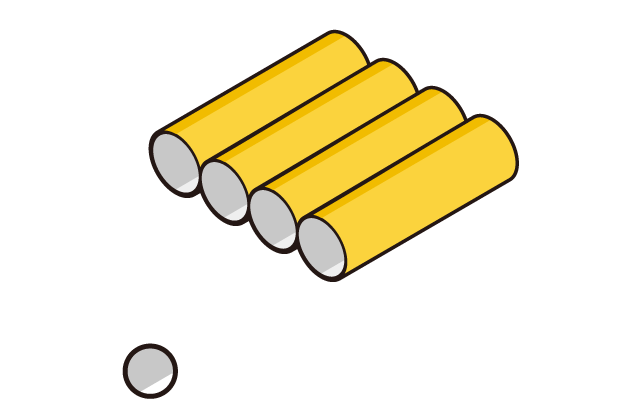

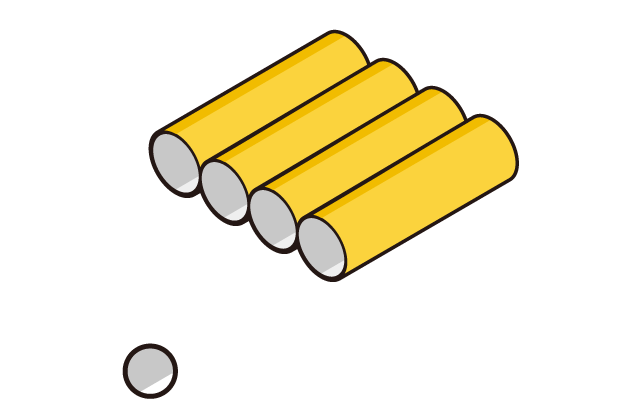

Sewn-Through Baffle Construction

This method is very simple and minimizes weight. The inside and outside layers are directly sewn together for lightweight and compact construction. This construction is used for summer bags.

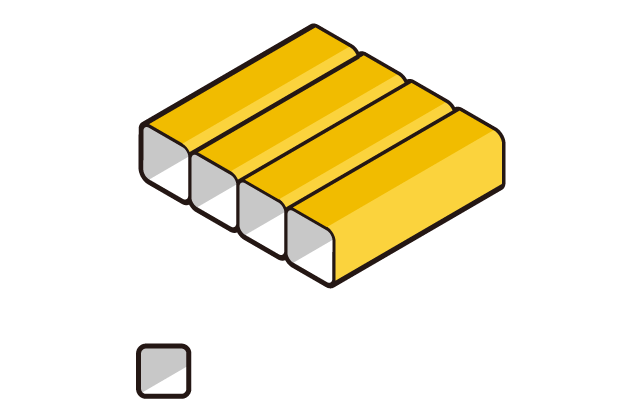

Box Baffle Construction

This is the most efficient method for optimizing the insulating quality of down. A breathable mesh is layered between the inside and outside layers, and is equipped with crosswise boxes to prevent clumping to one side.

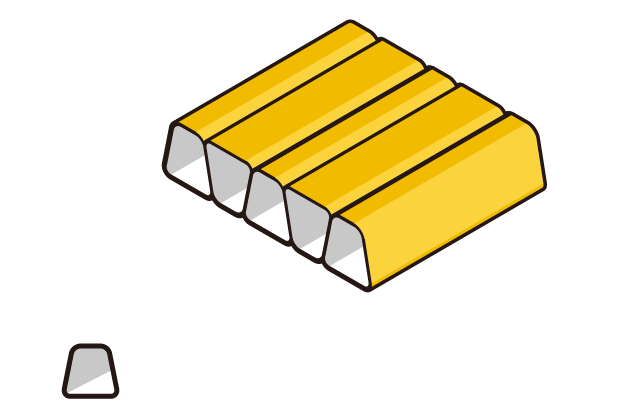

Trapezoid Box Baffle Construction

Boxes support each other in this construction; this maximizes the down's "loft," and efficiently insulates by minimizing clumping and heat release.

ABOUT THE MATERIALS 03

MATERIALS

About Materials for The Product

The materials used by NANGA

AURORA-TEX®

With both a shoulder warmer and draft tube, the entry of cold air is prevented. However, these features are available only in the trapezoid box quilt model.

Nylon

It is among the most lightweight of synthetic fibers, and offers elasticity and frictional strength. Dirt easily comes off of this smooth surface, making it easy to care for; it is minimally absorbent so it dries quickly even if it gets wet. It is compatible with many compounds, and can be used with water repellent or breathable waterproofing coatings.

* Denier A unit of fiber density. 1 Denier(dn) = a fiber with a weight of 1g at a length of 9,000m The higher the Deniers, the thicker the fiber; materials using thicker fibers are more durable.

AURORA-TEX®

With both a shoulder warmer and draft tube, the entry of cold air is prevented. However, these features are available only in the trapezoid box quilt model.

Nylon

It is among the most lightweight of synthetic fibers, and offers elasticity and frictional strength. Dirt easily comes off of this smooth surface, making it easy to care for; it is minimally absorbent so it dries quickly even if it gets wet. It is compatible with many compounds, and can be used with water repellent or breathable waterproofing coatings.

* Denier A unit of fiber density. 1 Denier(dn) = a fiber with a weight of 1g at a length of 9,000m The higher the Deniers, the thicker the fiber; materials using thicker fibers are more durable.

About the Down(Nanga)

ABOUT THE DOWN 01

QUALITY

A concern for quality

NANGA down is carefully selected at sites where it is produced, and aims at the highest quality. Washed and refined domestically, NANGA guarantees the utmost in quality.

NANGA uses the down from mature waterfowl. Because it is washed and refined domestically, it has the high functionality for temperature and humidity control that belongs essentially to down, and is sturdy without the smell that is peculiar to down.

ABOUT THE DOWN 02

FILLING MATERIALS

Hungarian Silver Goose(930FP DOWN)

Only Hungarian Silver Goose down is used, which is washed domestically. 90-7% down with a fill power of 930 FP, a very high degree of thermal insulation.

SPDX(860FP FEATHER)

Only Polish White Goose down of the highest quality is used, which is washed domestically. 93-7% down with a fill power of 860 FP, a very high degree of thermal insulation.

UDD(770FP FEATHER )

Ultrahydrophobic (super water-resistant) processing is added to DX down, yielding a high quality, high performance down with a fill power of 770 FP. Down and a water-repellant resin are joined at the molecular level, blocking the permeation of water by making a wall of fine particles. It is the highest grade of down, which "lets moisture pass through, but does not absorb water."

DX(760FP DC.FIBER)

Only European White Duck down is used, which is washed domestically. 90-10% down with a fill power of 760 FP. It is a high-quality down, excelling in cost and performance.

Fill power index (FP)

expresses the "down strength" and "resistance to pressure" according to standards for measuring down. A fill power of 760 means that if 30g of down is pressed down on with normal pressure in an experiment, it shows a resistance of 760 cubic inches. The higher the FP rating, the better the down is.

Bulkiness (Fill Power)

The quality of down is examined by the IDFL (International Down and Feather Testing Laboratory) of the United States, and only down that has met each fill power is used.

ABOUT THE DOWN 03

CERTIFICATE OF ORIGIN

Proof of Country of Origin

We attach proof of the country of origin for the down used in NANGA down products. This proves that NANGA down uses only European down.

HUNGARIAN SILVER GOOSE DOWN

POLISH WHITE GOOSE DOWN

EUROPEAN WHITE DUCK DOWN

WHITE DUCK DOWN

About European Norm(NANGA)

ABOUT EUROPEAN NORM 01

EUROPEAN NORM

About "European Norm"

For temperature ratings, NANGA uses the uniform standard used in European countries (European Norm).

EN (European Norm) is the name of the uniform standard that has been established in Europe. It is also called the European Standard. The calculation of temperature ratings for sleeping bags is defined by EN13537. Manufacturers used to calculate temperature ratings by their own methods, but now ratings are displayed based on unified criteria. Tests are conducted by authorized third parties for fairness. This is a big difference from temperature ratings based on manufacturers' own standards.

EN 13537 testing method

A mannequin equipped with temperature sensors is dressed in long sleeves and underwear down to the ankles, then laid inside a sleeping bag on top of a camping mattress. Temperature is measured at 5 locations inside the mannequin, and heat radiation levels are also measured. The measured temperatures and the room temperature in the laboratory are plugged into an equation to produce a value. A sleeping bag's ability to retain warmth is affected not only by the amount of stuffing, but also by the type and thickness of the fabric and accessories like zippers, so all these elements are judged comprehensively in the test.

European Norm Ratings

The temperature range at which an average adult woman can sleep without feeling cold. (Since women generally feel cold more easily than men, this level is calculated around 5℃ higher.)

The temperature range at which an average adult man can sleep for 8 hours curled up inside the sleeping bag (lower temperature limit). Temperatures lower than this are in a risky range.

The temperature range an average woman can handle for up to 6 hours curled up enough to hug her knees. The body will shiver in an attempt to product heat, and basal metabolism will increase. Using a sleeping bag at this temperature range also brings risk of hypothermia, and is extremely dangerous.

* Displayed temperatures are for reference only. Actual results vary widely between individuals depending on experience, strength, and physique. Please remember that the ratings are only for reference.

* Women should refer to Comfort, and men should refer to Limit.

How to Wash Down(Nanga)

NANGA DOWN GUIDE 01

DOWN CIRCULATION

The Nanga Down Cycle

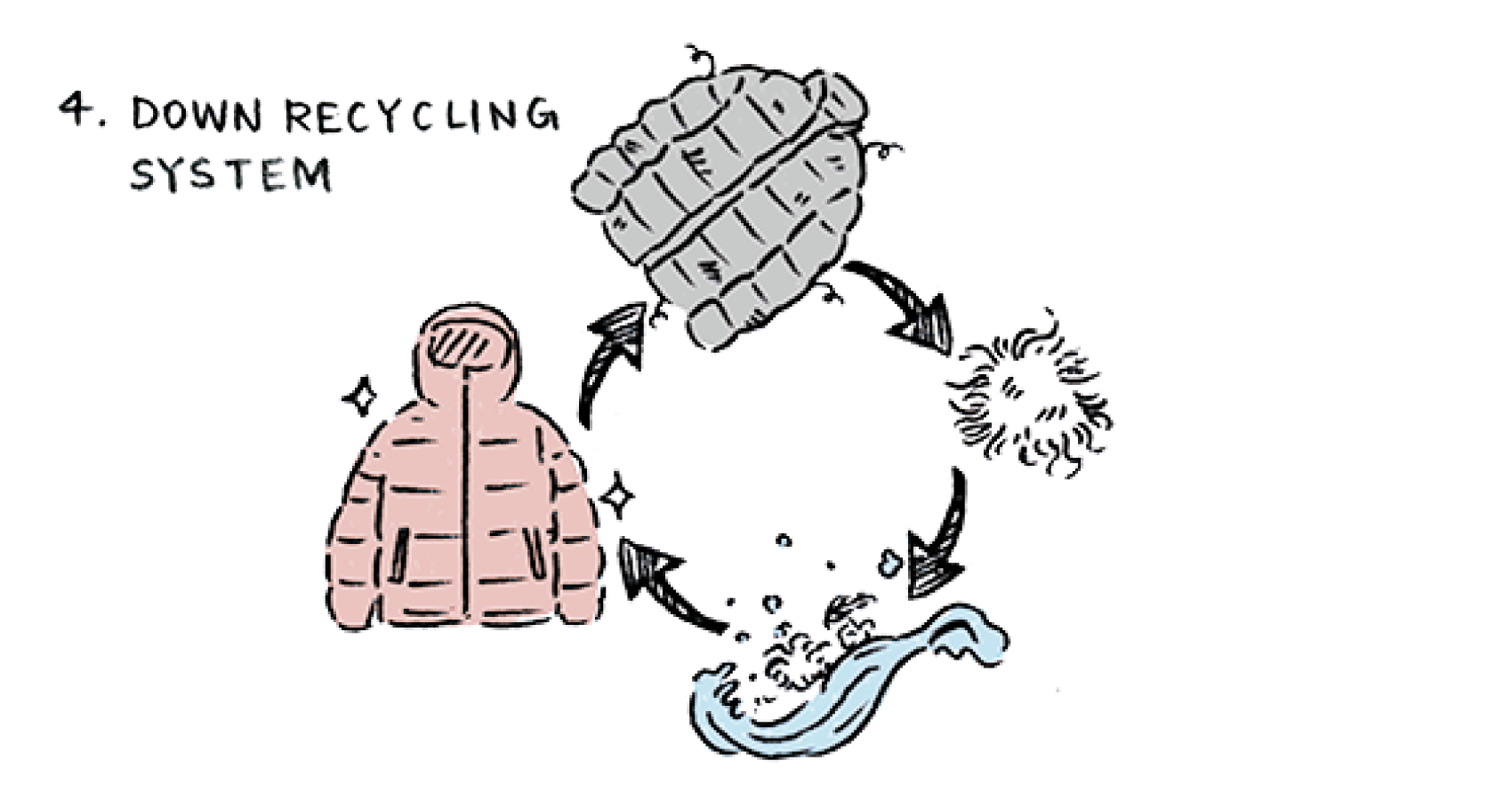

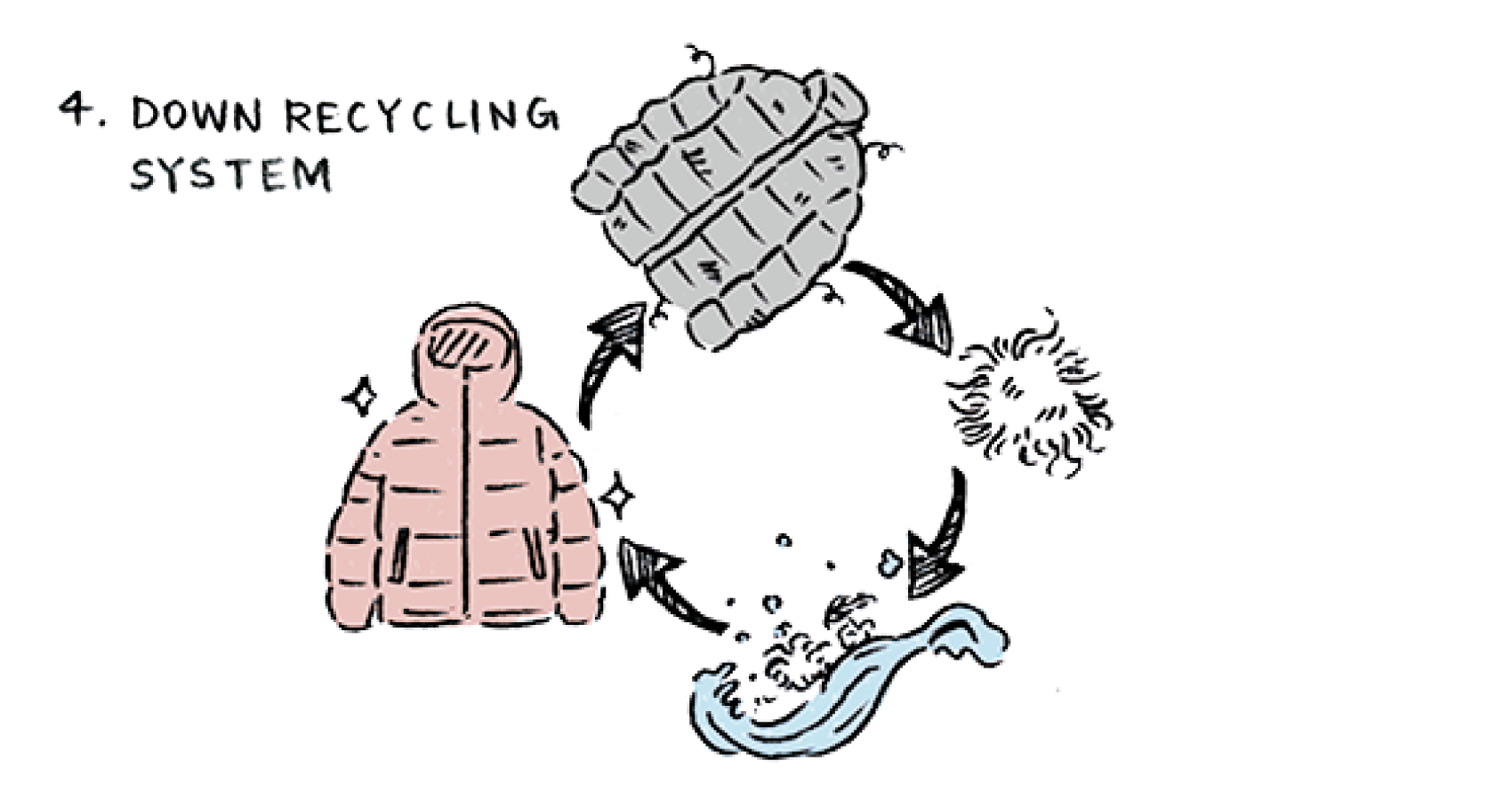

NANGA promotes a circulating life cycle of down

Learn more about its four-part cycle

The down used by NANGA begins as high-quality, raw down imported from overseas. It is then cleaned and processed by a Japanese down and feather manufacturer before being made into NANGA's finished products. These products can be used anywhere––from the city to the great outdoors––and their lifespans can be prolonged with proper care. When a down product finally becomes worn out, a recycling project allows that down to be brought back to life as a new product. NANGA promotes a circulating life cycle of down, and here are the four stages of that cycle.

Which part of the bird's feathers is referred to as down? The ins and outs of down.

The term "down" refers to the feathers that grow on the breasts of waterfowl. Down is light and offers great insulation, along with the ability to pass moisture into the atmosphere. Balls of down are known as "down clusters." Down is a precious material as it can only be collected in small quantities from a single bird and is not found on land fowl. Only waterfowl grow down as they need to protect themselves against the loss of body heat in their waterside habitats. The downs that are used as materials for manufactured products come primarily from two kinds of waterfowl: geese and ducks. Goose down is large. Its fine, soft fibers provide excellent insulation and water absorbency. In contrast, duck down is firm and springy, which gives it great resiliency. Duck downs are ideal for giving the products a firm loftiness.

Kawada Feather, Japan's leading specialist in down refinery.

The down that NANGA uses in its products goes through a cleaning process at Kawada Feather, a Japanese down and feather manufacturer. Raw waterfowl down is covered with dust and grime that is invisible to the naked eye; when left untreated, it can degrade the down's insulation performance as well as promote the growth of bacteria and dust mites. Situated on the Ise Plains in Mie Prefecture, Kawada Feather's main factory is fully equipped with the company's very own purification and processing equipment. The water provided by the bountiful, mountainous environment is a key factor in the cleaning and purification process. The dry climate promotes the down to expand, which further enhances the factory's ability to remove dirt. The pristine and super soft quality of the water is perfect for washing away dander. Kawada Feather reaps the full benefits of its environment, advanced technology, and human craftsmanship to produce beautiful down.

Down can be washed at home! Learn the proper way to wash down.

Washing down products will degrade their quality––this is a very common misconception. The truth is that proper washing will cleanse the down of absorbed perspiration and oils, bringing back its fluffiness. There is no need for frequent washing. However, we would like to share with you the correct method for washing down, so that you can comfortably enjoy the full benefits of down products.

01

Place the down in a mesh laundry bag.

02

Choose the same setting on your washing machine that you would use for a blanket.

03

Do not use the spin cycle. Instead, wring the down out by hand and dry it in a shaded area out of direct sunlight. Then, pat it down with both hands, and even out any wrinkles.

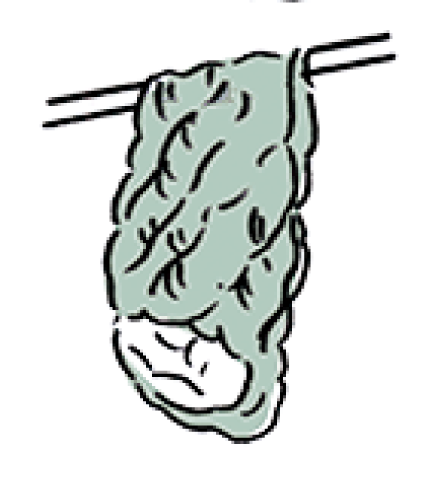

Green Down: The down recycling project

The Green Down Project advocates the reuse of down, which is a finite resource. The aim is to collect down products that are no longer being used, regardless of the manufacturer, and refines the downs to repurpose them as new products. The project offers several benefits.

The key benefits of recycling down

Environmental impact

Reduces waste, reuses resources, limits carbon dioxide emissions, provides environmental education

Promotes the employment of persons with disabilities

Commissioning of down product sorting and disassembly processes

Contributes to local economies

Partnership with the Red Feather (Central Community Chest of Japan)

Provides stable supply of down

Increased supply and stabilized prices through recycling

TECHNOLOGY 01

YKK × NANGA

NANGA x YKK parts which reduce snagging and catching

Our sleeping bags are equipped with specialized YKK parts on zipper sliders to minimize snagging and catching of the fabric

When using a sleeping bag, there is a risk of the zipper catching on the super-thin fabric and preventing the opening and closure of the bag. If severely snagged, the zipper may even cause damage to the fabric. To mitigate such problems, we have attached special YKK parts to the zipper sliders. These parts are developed to diminish the gaps in the zipper slider that causes the snagging, resulting in fewer occurrences of the fabric getting caught as well as reduced damage to the fabric in case of such events. Furthermore, the parts are made from lightweight resin (weighing 1.6 g per piece) with phosphorescent features for easier operation in the dark.

Due to the concave design of the specialized YKK zippers, the fasteners guide the fabric towards the center, reducing any chance of snagging or catching.

With our phosphorescent technology, finding your zippers in your dark tent will no longer become a hassle.

Due to the concave design of the specialized YKK zippers, the fasteners guide the fabric towards the center, reducing any chance of snagging or catching.

With our phosphorescent technology, finding your zippers in your dark tent will no longer become a hassle.

TECHNOLOGY 02

SOLID STRUCTURE

The next-level sleeping bag construction

All NANGA sleeping bags are constructed following a trapezoid box baffle pattern structure which brings out the full potential of down. This simple yet sophisticated pattern structure allows any user to absorb the maximum amount of heat possible. The sleek design of our sleeping bags realistically tailors to the human body making it the most efficient in size and capacity.

01. Trapezoid box baffle structure

What makes this pattern structure so efficient is that it prevents the down from bunching up, and also plays a role in reducing the overall weight of the sleeping bag. As the geometric structure supports each other, the full potential of the down is maximized. By reducing the heat radiation, it eliminates any potential bunching, and evenly distributes even heat throughout the sleeping bag.

02. Foot box

A distinguishing feature of this structure is that it prevents the down from bunching up, and allows for a reduction in weight. Because each of the boxes supports each other, the full loft potential of the down is maximized, and by reducing any diminished heat radiation through potential bunching, heat retention is efficiently distributed throughout the bag.

03. Shoulder warmer & draft tube

Our shoulder warmer and draft tube prevents any cold air from entering the sleeping bag.

*This feature is only available with our trapezoid box quilt models

04. Three-dimensional hood

During the cold seasons, its crucial to keep your head warm. The three dimensional hood equipped in specific models blankets your head, and functionally retains the heat so you can stay warm longer. The fastener was designed near the top of the sleeping bag, making zipping up and down your sleeping bag a breeze.

ABOUT THE MATERIALS 01

FUNCTION

About Functionality

Introducing the functionality that integrates NANGA's technology and philosophy

At NANGA, we only work with the finest materials in order to create high quality products. Through rigorous tests, our skilled artisans meticulously hand select the imported European white duck down that was shipped overseas to us in Japan. A sophisticated refining process is a crucial step in our development process as it maximizes the potential of the characteristics of the down.

By using the locking drawstring it is possible to adjust temperature and fit.

Insulating material in the shoulder area prevents warm air from escaping. Equipped primarily on 3 and 4 season sleeping bags.

Internal tube blocks cold air from coming in through the gaps in the zipper, preserving warmth. Equipped primarily on 3 and 4 season sleeping bags, same as the shoulder warmer.

Equipped with YKK5C. Considered to be the optimal zipper for sleeping bags based on strength testing by YKK.

The regular size has a max length of 210cm and a max width of 80cm, making for a comfortable bag. We also offer long and short versions.

ABOUT THE MATERIALS 02

CONSTRUCTION

About Product Construction

The 3 quilting structures used by NANGA. We leverage a deep understanding of the strengths of each type to identify the optimal application for each product.

This sleeping bag features a new level of technology, with a trapezoid box baffle structure and solid structure which maximizes the full potential of down, and allows stress-free and efficient heat retention no matter what position you sleep in. By narrowing the feet area, we have successfully reduced weight.

Sewn-Through Baffle Construction

This method is very simple and minimizes weight. The inside and outside layers are directly sewn together for lightweight and compact construction. This construction is used for summer bags.

Box Baffle Construction

This is the most efficient method for optimizing the insulating quality of down. A breathable mesh is layered between the inside and outside layers, and is equipped with crosswise boxes to prevent clumping to one side.

Trapezoid Box Baffle Construction

Boxes support each other in this construction; this maximizes the down's "loft," and efficiently insulates by minimizing clumping and heat release.

ABOUT THE MATERIALS 03

MATERIALS

About Materials for The Product

The materials used by NANGA

AURORA-TEX®

With both a shoulder warmer and draft tube, the entry of cold air is prevented. However, these features are available only in the trapezoid box quilt model.

Nylon

It is among the most lightweight of synthetic fibers, and offers elasticity and frictional strength. Dirt easily comes off of this smooth surface, making it easy to care for; it is minimally absorbent so it dries quickly even if it gets wet. It is compatible with many compounds, and can be used with water repellent or breathable waterproofing coatings.

* Denier A unit of fiber density. 1 Denier(dn) = a fiber with a weight of 1g at a length of 9,000m The higher the Deniers, the thicker the fiber; materials using thicker fibers are more durable.

AURORA-TEX®

With both a shoulder warmer and draft tube, the entry of cold air is prevented. However, these features are available only in the trapezoid box quilt model.

Nylon

It is among the most lightweight of synthetic fibers, and offers elasticity and frictional strength. Dirt easily comes off of this smooth surface, making it easy to care for; it is minimally absorbent so it dries quickly even if it gets wet. It is compatible with many compounds, and can be used with water repellent or breathable waterproofing coatings.

* Denier A unit of fiber density. 1 Denier(dn) = a fiber with a weight of 1g at a length of 9,000m The higher the Deniers, the thicker the fiber; materials using thicker fibers are more durable.

ABOUT THE DOWN 01

QUALITY

A concern for quality

NANGA down is carefully selected at sites where it is produced, and aims at the highest quality. Washed and refined domestically, NANGA guarantees the utmost in quality.

NANGA uses the down from mature waterfowl. Because it is washed and refined domestically, it has the high functionality for temperature and humidity control that belongs essentially to down, and is sturdy without the smell that is peculiar to down.

ABOUT THE DOWN 02

FILLING MATERIALS

Hungarian Silver Goose(930FP DOWN)

Only Hungarian Silver Goose down is used, which is washed domestically. 90-7% down with a fill power of 930 FP, a very high degree of thermal insulation.

SPDX(860FP FEATHER)

Only Polish White Goose down of the highest quality is used, which is washed domestically. 93-7% down with a fill power of 860 FP, a very high degree of thermal insulation.

UDD(770FP FEATHER )

Ultrahydrophobic (super water-resistant) processing is added to DX down, yielding a high quality, high performance down with a fill power of 770 FP. Down and a water-repellant resin are joined at the molecular level, blocking the permeation of water by making a wall of fine particles. It is the highest grade of down, which "lets moisture pass through, but does not absorb water."

DX(760FP DC.FIBER)

Only European White Duck down is used, which is washed domestically. 90-10% down with a fill power of 760 FP. It is a high-quality down, excelling in cost and performance.

Fill power index (FP)

expresses the "down strength" and "resistance to pressure" according to standards for measuring down. A fill power of 760 means that if 30g of down is pressed down on with normal pressure in an experiment, it shows a resistance of 760 cubic inches. The higher the FP rating, the better the down is.

Bulkiness (Fill Power)

The quality of down is examined by the IDFL (International Down and Feather Testing Laboratory) of the United States, and only down that has met each fill power is used.

ABOUT THE DOWN 03

CERTIFICATE OF ORIGIN

Proof of Country of Origin

We attach proof of the country of origin for the down used in NANGA down products. This proves that NANGA down uses only European down.

HUNGARIAN SILVER GOOSE DOWN

POLISH WHITE GOOSE DOWN

EUROPEAN WHITE DUCK DOWN

WHITE DUCK DOWN

ABOUT EUROPEAN NORM 01

EUROPEAN NORM

About "European Norm"

For temperature ratings, NANGA uses the uniform standard used in European countries (European Norm).

EN (European Norm) is the name of the uniform standard that has been established in Europe. It is also called the European Standard. The calculation of temperature ratings for sleeping bags is defined by EN13537. Manufacturers used to calculate temperature ratings by their own methods, but now ratings are displayed based on unified criteria. Tests are conducted by authorized third parties for fairness. This is a big difference from temperature ratings based on manufacturers' own standards.

EN 13537 testing method

A mannequin equipped with temperature sensors is dressed in long sleeves and underwear down to the ankles, then laid inside a sleeping bag on top of a camping mattress. Temperature is measured at 5 locations inside the mannequin, and heat radiation levels are also measured. The measured temperatures and the room temperature in the laboratory are plugged into an equation to produce a value. A sleeping bag's ability to retain warmth is affected not only by the amount of stuffing, but also by the type and thickness of the fabric and accessories like zippers, so all these elements are judged comprehensively in the test.

European Norm Ratings

The temperature range at which an average adult woman can sleep without feeling cold. (Since women generally feel cold more easily than men, this level is calculated around 5℃ higher.)

The temperature range at which an average adult man can sleep for 8 hours curled up inside the sleeping bag (lower temperature limit). Temperatures lower than this are in a risky range.

The temperature range an average woman can handle for up to 6 hours curled up enough to hug her knees. The body will shiver in an attempt to product heat, and basal metabolism will increase. Using a sleeping bag at this temperature range also brings risk of hypothermia, and is extremely dangerous.

* Displayed temperatures are for reference only. Actual results vary widely between individuals depending on experience, strength, and physique. Please remember that the ratings are only for reference.

* Women should refer to Comfort, and men should refer to Limit.

NANGA DOWN GUIDE 01

DOWN CIRCULATION

The Nanga Down Cycle

NANGA promotes a circulating life cycle of down

Learn more about its four-part cycle

The down used by NANGA begins as high-quality, raw down imported from overseas. It is then cleaned and processed by a Japanese down and feather manufacturer before being made into NANGA's finished products. These products can be used anywhere––from the city to the great outdoors––and their lifespans can be prolonged with proper care. When a down product finally becomes worn out, a recycling project allows that down to be brought back to life as a new product. NANGA promotes a circulating life cycle of down, and here are the four stages of that cycle.

Which part of the bird's feathers is referred to as down? The ins and outs of down.

The term "down" refers to the feathers that grow on the breasts of waterfowl. Down is light and offers great insulation, along with the ability to pass moisture into the atmosphere. Balls of down are known as "down clusters." Down is a precious material as it can only be collected in small quantities from a single bird and is not found on land fowl. Only waterfowl grow down as they need to protect themselves against the loss of body heat in their waterside habitats. The downs that are used as materials for manufactured products come primarily from two kinds of waterfowl: geese and ducks. Goose down is large. Its fine, soft fibers provide excellent insulation and water absorbency. In contrast, duck down is firm and springy, which gives it great resiliency. Duck downs are ideal for giving the products a firm loftiness.

Kawada Feather, Japan's leading specialist in down refinery.

The down that NANGA uses in its products goes through a cleaning process at Kawada Feather, a Japanese down and feather manufacturer. Raw waterfowl down is covered with dust and grime that is invisible to the naked eye; when left untreated, it can degrade the down's insulation performance as well as promote the growth of bacteria and dust mites. Situated on the Ise Plains in Mie Prefecture, Kawada Feather's main factory is fully equipped with the company's very own purification and processing equipment. The water provided by the bountiful, mountainous environment is a key factor in the cleaning and purification process. The dry climate promotes the down to expand, which further enhances the factory's ability to remove dirt. The pristine and super soft quality of the water is perfect for washing away dander. Kawada Feather reaps the full benefits of its environment, advanced technology, and human craftsmanship to produce beautiful down.

Down can be washed at home! Learn the proper way to wash down.

Washing down products will degrade their quality––this is a very common misconception. The truth is that proper washing will cleanse the down of absorbed perspiration and oils, bringing back its fluffiness. There is no need for frequent washing. However, we would like to share with you the correct method for washing down, so that you can comfortably enjoy the full benefits of down products.

01

Place the down in a mesh laundry bag.

02

Choose the same setting on your washing machine that you would use for a blanket.

03

Do not use the spin cycle. Instead, wring the down out by hand and dry it in a shaded area out of direct sunlight. Then, pat it down with both hands, and even out any wrinkles.

Green Down: The down recycling project

The Green Down Project advocates the reuse of down, which is a finite resource. The aim is to collect down products that are no longer being used, regardless of the manufacturer, and refines the downs to repurpose them as new products. The project offers several benefits.

The key benefits of recycling down

Environmental impact

Reduces waste, reuses resources, limits carbon dioxide emissions, provides environmental education

Promotes the employment of persons with disabilities

Commissioning of down product sorting and disassembly processes

Contributes to local economies

Partnership with the Red Feather (Central Community Chest of Japan)

Provides stable supply of down

Increased supply and stabilized prices through recycling